Case Study: Acer Engineers Automated Material Feed System with Electrical Components

Acer Engineers Automated Material Feed System Supplied with Electrical Components from Lakeland Engineering Equipment Company

How the Ranger Paves the Way for the Truss Industry & Sets the Pace of Production

OVERVIEW

Acer Inc. was developing their first automated material handling system based on pneumatics/vacuum. They knew there was a need for this type of machinery within the truss industry and Steve Aylsworth, co-owner and leading engineer of Acer, began developing this system with the help of his team.

The Ranger required a complete motor control system and a laser measuring scanner. Being unsatisfied with a distributor they had worked within the past, and having previous ties to Lakeland, Acer again looked to Lakeland Engineering Equipment Company to find solutions for a complete motor control system and an advanced laser.

GOALS

- To automate the feed and handling of lumber

- To establish the first of its kind in the industry

- Increase productivity

- Reduce labor costs

- Limit downtime

- Find cost-effective component solutions

- Cutting-edge laser capabilities

- Pneumatic/Vacuum driven

OUTCOME

Acer developed the first automated lumber handling solution which is known today as the Ranger. It has the fastest cycle time in the industry, is fully-automated, sets the pace of production, and drives down labor costs and more. This system is fit with electrical AC Servo motor control components and sensors from Lakeland Engineering Equipment Company that satisfied their goals of being cost-effective, safety-oriented and efficient.

Download the full Case Study.

THE STORY

The First Phase of Acer Inc.

Steve and Carol Aylsworth started Acer Inc. in 1996 with a history of working in the truss industry. Carol, a knowledgeable industry and business professional and Steve, an innovative design engineer, have always made a great team, previously founding a manufacturing and design business for large recycling balers. This is where the relationship between Todd Spinner of Lakeland Engineering Equipment Company and Steve and Carol Aylsworth began.

Prior to the development of the material feed system, known today as the Ranger, Acer was involved in the development and creation of prototypes of bunk feeders that were sold with the Koskovich Company Automated Omni Saws. This proved to be a successful venture, with Acer building 104 bunk feeders total sold under the Koskovich brand.

Steve was continuously looking for ways to improve this system, its efficiency and its reliability. When the economy took a downturn in 2008, the manufacturing of these bunk feeders slowed. This allowed Steve to channel his time, energy and creative engineering into developing the next phase of the company.

Development of the Ranger by Acer

“Steve was tired of dealing with a hydraulic system so he went to the drawing board and began development on an electrical and pneumatic-based retrieval system,” said Carol. “His mind is always on – always coming up with new and improved ways to make things work.”

“The goal with this system was to automate the feed of saws in the truss industry,” said Steve. “The advantages of an automated system over a person are that the machine never makes a mistake. You take the possibility of operator error out of the equation.” The Acer team knew that there was a need for this within in the industry and that it had never been done before.

“The machine works on command from the saw through a computer network,” said Steve “It drives the pace of production as the machine works continuously and is more consistent.” As Steve began designing and writing the algorithms for this system along with the Acer team, the next step was to find solutions for the laser measuring sensor and a complete motor control system.

Finding the Right Electrical Control System Solutions

At the time, Acer was using a couple different suppliers including Lakeland Engineering Equipment Company. “We had a past history with Lakeland and Todd at the former company we owned,” said Steve, “We’ve known each other for more than 25-years.”

Although Acer did take into consideration the other supplier they had also been working with for some of their components, they elected to go with Lakeland Engineering based on a number of contributing factors. “We were looking for something else to meet our needs, and the other supplier we had worked with on other projects was too expensive,” Steve explained. “Todd and Lakeland also brought in a lot of new components including pneumatic information that we hadn’t been exposed to before.”

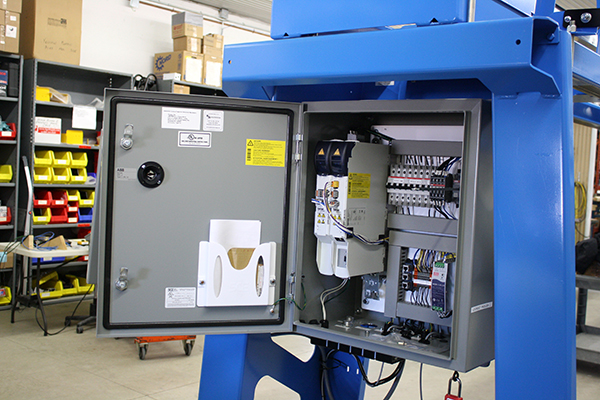

The Lakeland and Acer teams worked together to find the solutions they needed for their motor control center on the Ranger. These products included: Lenze, Pepperl+ Fuchs, Leuze, ABB and more. Acer’s needs for sensors, safety equipment, drives, motors and more were met with products from Lakeland’s suppliers. “One of the best things about Lakeland is their breadth of product line,” said Steve. “Todd regularly brings in factory reps to assist us based on the solution that we need. With the development of the Ranger, some of the OEMs also provided product assistance including Pepperl+Fuchs and Lenze.”

Lakeland, Acer and the OEMs worked together to find the best possible solutions based on the requirements of the Ranger.

Overcoming Challenges

Through the process of developing the Ranger, the Acer team did encounter a few challenges. The greatest challenge was finding the correct laser scanning technique. Steve spent the time researching what type of sensor the Ranger would require and wrote the algorithms for the sensor to work seamlessly with all of the moving parts of the Ranger. The sensor had to be precise, quick and on the cutting-edge of technology.

Steve had found the sensor that was believed to meet the project requirements and was needed for testing. This sensor was manufactured in Belarus and at the time was only sold by one rail-specific distributor within the United States. This distributor did not want to sell outside of the industry. “I called Todd and explained the situation and what we needed,” said Steve. “Lakeland set the sensor manufacturer up as a supplier in order to provide the solution that we needed. From there, I tested my algorithms and found that this was the perfect solution.”

Reminiscing on the relationship with Lakeland, Steve commented, “Our relationship with Lakeland has been good, we’ve enjoyed it. Todd’s an extraordinary sales guy – that is missing a lot in this world. I’ve dealt with sales people for a long long time, and once in a while somebody comes along that is really good. Todd’s one of those people.”

Explaining the necessity of the laser, Steve said, “It’s all about production for the truss plants – speed is important to them. This laser is used to measure and profile the shape of the lumber – it helps us know where the lumber is and make decisions about where the next station goes. It’s advanced enough to know where the leading edge of the lumber is.” The scanning system also allows Acer to work at incredible speeds – reading 90 inches per second.

used to measure and profile the shape of the lumber – it helps us know where the lumber is and make decisions about where the next station goes. It’s advanced enough to know where the leading edge of the lumber is.” The scanning system also allows Acer to work at incredible speeds – reading 90 inches per second.

“In 2008 we began making prototypes of the Ranger,” said Steve and Carol. “In 2010 we had the first working machine and in 2011, we installed it.” Since 2011, Acer’s business continues to flourish, working with the top saw manufacturers in the industry – MiTek and Hundegger.

Acer attended and showcased the Ranger at the Building Component Manufacturers Conference (BCMC) alongside MiTek. This annual show is a trusted venue for structural building component manufacturers to learn about the latest ideas, products and trends throughout their entire supply chain. The response was positive and allowed them the opportunity to connect with end users.

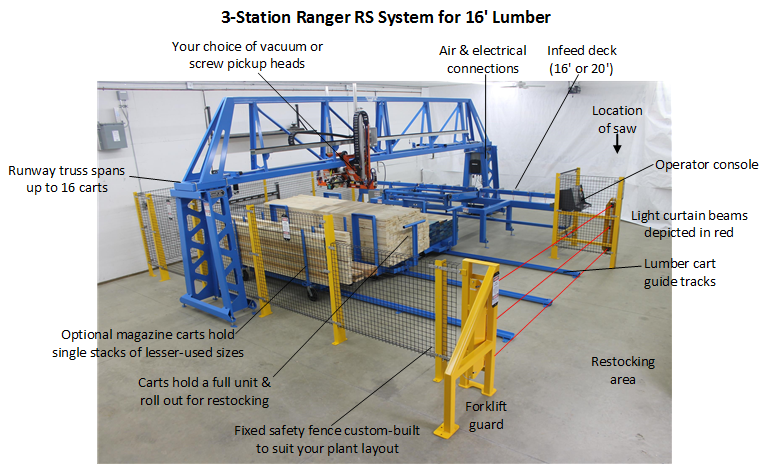

Capabilities of the Ranger

The Ranger is a fully automatic Laser Guided Lumber Retrieval System designed to complement a linear-feed saw. Acer’s engineering staff can optimize the machine for your plant with different loading configurations, storage capacity and a choice of screw pickup or vacuum pickup. The Ranger has the fastest cycle time in the industry.

The vacuum pickup system was designed by Steve, based off pneumatics and built specifically for lumber handling. It is engineered in-house to ensure reliability and quality. With a number of custom pieces, one must ask where the team gets their inspiration from.

“My inspiration comes from all over,” Steve grinned. “I have a lot of great help around here that make our business possible.” Carol agreed stating, “Often, Hundegger or MiTek may have a certain need and they look to us to find a solution. It’s important for us to talk to end users on a regular basis to ensure that we stay on the cutting-edge of technology and design.”

Acer builds the Rangers up to 100 feet long, allowing a greater range of capabilities including the ability to handle more material. “The Ranger can accommodate up to 17 stations with multiple magazines underneath. This allows for a larger variety of lumber for the machine to choose from, without having to stop production when the material needs to be switched-out to a different size.”

“Steve’s nickname is the Wizard,” said Todd, “He always makes things better – that’s the way his mind works, no one in the market place can touch this design. It is the best of the best.”

“The Ranger combined with the high-tech saws cuts waste material down,” said Steve. “The saw’s modified CAD system downloads a recipe,” explained Steve. “The Ranger then optimizes all of the ingredients of the recipe – it’s all computer-driven and almost completely hands-off.”

In fact, the saws can look to the Ranger to tell what lengths the material is and nest them in the most efficient manner. Steve explained, “With these systems working together, we increase efficiency and cut waste simultaneously.” The autonomous operation also saves on labor costs, since the saw operator can oversee the Ranger.

Beyond spearheading the Ranger, Acer is unique in that their agile and innovative engineering staff design and manufacture all major components of their machinery. Acer has their own CNC press brake, machining center and lathe for superior design and quality.

The ACER INC Team: Dan, Scott, Steve, Jason, Carol, Rob, Mark, and Rick. (Not Pictured: Jim)

The ACER INC Team: Dan, Scott, Steve, Jason, Carol, Rob, Mark, and Rick. (Not Pictured: Jim)

To learn more about the Ranger’s capabilities and the Acer team, visit the Acer Inc. website.

What’s next for Acer Inc.?

Since the development of the Ranger, the Acer team has continued to manufacture the Ranger and all major components on this equipment. “It’s been a very mutually-beneficial relationship and I’ve enjoyed working with and getting to know them on a personal level,” said Todd. “The Acer team presented new challenges for us, which gave Lakeland the opportunity to improve our organization and processes to ensure we continue to meet the needs of all of our customers.”

equipment. “It’s been a very mutually-beneficial relationship and I’ve enjoyed working with and getting to know them on a personal level,” said Todd. “The Acer team presented new challenges for us, which gave Lakeland the opportunity to improve our organization and processes to ensure we continue to meet the needs of all of our customers.”

Acer Inc. continues to make their revolutionary design, setting the pace for the truss industry. The Acer team is also working on a number of exciting projects. “We are toward the end of a major software development with the help of Control Assemblies,” said Steve. “This is a huge step forward in machine handling software. The developments include new features that lessen the Ranger to saw travel time, checking the curvature of the lumber with the help of Pepperl + Fuchs sensors, and enhanced overall functionality.”

In addition, Steve invented and wrote the software for a new device that will greatly increase the speed of production. This is sure to create a buzz within the industry. Look for these enhancements coming to fruition in 2018. To stay up-to-date on all of the latest developments and features from Acer and learn more about their business, visit acerinc.com.

For more information about this case study or the electrical components mentioned, please contact Lakeland Engineering Equipment Company.

About Acer Inc.

Founded in 1996, Acer Inc. is deeply rooted in innovative design and quality manufacturing with over 18-years in the truss industry. Today we are still innovating, with the introduction and continued success of the Ranger RS lumber retrieval system. Invented and manufactured by Acer, the Ranger RS is one of the most cost-effective and reliable products to be introduced to this market.

Acer is somewhat unusual in that we design and manufacture all major components of our machinery. As the needs of our customers change, we respond with new ideas and sophisticated solutions. From forming and welding, to machining, painting, and wiring, our skilled and versatile employees do it all in-house. We devote significant resources to research and development, and evolve our designs as the industry changes. We strongly believe in providing a safe, comfortable work environment and stable employment for our staff. Their loyalty and hard work show in the quality of the machinery we build. Our thorough design analysis, careful workmanship, and comprehensive testing ensure the machinery we build will operate reliably and profitably for many years.

To learn more about Acer Inc., contact them today.