Wire Management Solutions – Benefits of Modular Connectors

How the HARTING Han-Modular® Series Saves Time and Space while Improving Flexibility

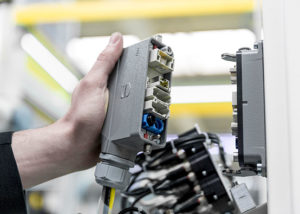

Did you know that an increasing number of OEMs are opting for connectors over hard wiring solutions to save space and time while increasing flexibility? HARTING’s Han-Modular® Series is mixed media industrial rectangular connectors that allow power, signal, and data to be combined into one connection point.

OEMs have already seen the benefits of this series, including:

Space Savings

Space Savings

- Combine multiple connectors into a single connector to take up less space on the product.

- Flexibility

- Change the engineered design throughout the process without changing the footprint of the connector – switch out modules as design changes.

- Low-maintenance

- End users can connect and disconnect with this plug and play solution. If the connector needs to be replaced, rehardwiring is not needed.

- Smart

- Bring intelligence to the connector level with Han-Modular® as your gateway to the IIoT.

Get an up-close look at the Han-Modular® Series and how it works by watching the video below.

Modular Connector Resources and Application Assistance

The space saving, flexible, smart and low maintenance Han-Modular® Series may provide the right solution for your application. To learn more about application uses, safety standards and ratings, size and connection parameters, cost savings and more, check out the helpful resources below.

The space saving, flexible, smart and low maintenance Han-Modular® Series may provide the right solution for your application. To learn more about application uses, safety standards and ratings, size and connection parameters, cost savings and more, check out the helpful resources below.

- Connectors Outperform Hardwiring White Paper

- Modular Connectors Outperform Hardwiring

- Rectangular and Circular Connectors

- Configurator and Cost Savings Calculator Application

- HARTING Han-Modular® Website

Lakeland Engineering Equipment Company is an authorized distributor of the HARTING line. We carry a variety of connectors and wire management solutions to fit the needs of all customers. Lakeland’s experienced sales team works directly with you and our umbrella of resources to provide the best solution to meet your specific application requirements. For local, in-person support and application assistance, contact us today.

If you’re considering switching from a permanent hardwired solution to a connector like the HARTING Han-Modular® Series, read on to learn more about the advantages of modular connectors over hardwired solutions and circular connectors.

Which Wire Management Solution is Right for My Application?

Hardwiring versus Connectors

When comparing ways to bring power, signal, or data into an application – one of the first questions to ask is how frequently the application will be disconnected or reconnected.

- Hardwiring

- When hardwiring, each wire needs to be removed and reconnected, resulting in substantial time and labor costs. If anything is miswired, it can take hours of troubleshooting to correct.

- Connectors

- While using a connector costs more upfront, once the connector is made, it’s a plug-and-play solution. It is also impossible to miswire and does not require skilled labor.

Circular Connectors versus Rectangular Connectors

Has converting from a permanent hardwired solution to a connector piqued your interest? If so, there are still two options to consider when it comes to what type of connector would work best for your application – circular or rectangular.

- Circular connectors

- Circular connectors require more space. They are twisted into place, requiring additional space for a hand.

- Connector manufacturers most often have to design custom modular circular connectors resulting in long lead times and less flexibility.

- Rectangular connectors

- Rectangular connectors allow for a smaller end device. These connectors are locked into place with latching mechanisms on either the inside or outside of the connector and can be placed right next to each other – saving substantial space.

- Rectangular connectors allow for user-defined customization with off-the-shelf modules. This allows a significant improvement in flexibility and modularity.

For more information or application assistance, contact Lakeland Engineering Equipment Company.